Détermination des propriétés mécaniques, rhéologiques et physicochimiques d’un biocomposite à base de PP recycle et des fibres de feuilles de Rônier

- Post by: SOAPHYS-KZ

- 17 juin 2024

- Comments off

https://doi.org/10.46411/jpsoaphys.2023.021

Section de la parution: Informations de publication

J. P. Soaphys, Vol 3, N°2 (2023) CJKA04

Pages : CJKA04-1 à CJKA04-9

Informations sur les auteurs

Coumba THIANDOUME, Papa Mbaye DIOUF*, Babacar NIANG, Sajith T. ABDULRAHMAN, Ousmane NDOUR, Elhadji Babacar LY, Sabu THOMAS, Adams TIDJANI

1Laboratoire de Rayonnements Naturels et Artificiels, Département de Physique, Université Cheikh Anta Diop de Dakar, Dakar, Sénégal

2Section de Physique Appliquée, Unité de Formation et de Recherche de Sciences Appliquées et de Technologie, Université Gaston Berger, Saint-Louis, Sénégal

3International and Inter University Center of Nanoscience and Nanotechnology, Mahatma Gandhi University, Kottoyam, Kerela, India

4India School of Chemistry, Mahatma Gandhi University, Kottoyam, Kerela, India

Corresponding author e-mail papambaye.diouf@ucad.edu.sn

RESUME

Du

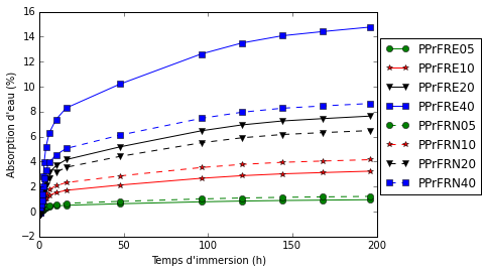

polypropylène recyclé (PPr) à partir des déchets plastiques de post-consommation a été avec des fibres issues de la feuille du Rônier pour la conception de biocomposites bois polymère. Deux groupes de fibres ont été utilisés à savoir les FRN et les FRE. L’analyse infrarouge à transformer de Fourier, le test de traction, le test de dureté, le test rhéologique ainsi que le test d’absorption d’eau ont été effectués pour déterminer les caractéristiques physicochimiques des biocomposites. L’analyse infrarouge a montré que le mélange entre la fibre et matrice est purement physique. La résistance à la traction a diminué en fonction du taux de renforts aussi bien pour les FRE que pour les FRN. Cette diminution est plus significative avec les FRE. Le module de Young a augmenté avec des taux élevés de FRN. Cependant, il a diminué avec les taux élevés de FRE. La dureté a augmenté avec les taux de FRE et de FRN. Avec l’ajout des fibres végétales le module de stockage G’ ainsi que le module de perte G » ont augmenté en fonction de la fréquence angulaire. La viscosité complexe et la capacité d’absorption d’eau ont également été augmenté par l’ajout de la fibre végétale.

Mots-Clés : Polypropylène recyclé, Feuille de Rônier, Biocomposite, Rhéologie

AlMaadeed, M.A., Kahraman, R., Noorunnisa Khanam, P., Madi, N., 2012. Date palm wood flour/glass fibre reinforced hybrid composites of recycled polypropylene: Mechanical and thermal properties. Mater. Des. 42, 289–294. https://doi.org/10.1016/j.matdes.2012.05.055

Andrzejewski, J., Szostak, M., Barczewski, M., Łuczak, P., 2019. Cork-wood hybrid filler system for polypropylene and poly(lactic acid) based injection molded composites. Structure evaluation and mechanical performance. Compos. Part B Eng. 163, 655–668. https://doi.org/10.1016/J.COMPOSITESB.2018.12.109

Ares, A., Bouza, R., Pardo, S.G., Abad, M.J., Barral, L., 2010. Rheological, mechanical and thermal behaviour of wood polymer composites based on recycled polypropylene. J. Polym. Environ. 18, 318–325. https://doi.org/10.1007/s10924-010-0208-x

Bansal, S., Kumar, N., Jindal, P., 2017. Effect of MWCNT Composition on the Hardness of PP/MWCNT Composites. Mater. Today Proc. 4, 3867–3871. https://doi.org/10.1016/j.matpr.2017.02.285

Bettini, S.H.P., De Miranda Josefovich, M.P.P., Muñoz, P.A.R., Lotti, C., Mattoso, L.H.C., 2013. Effect of lubricant on mechanical and rheological properties of compatibilized PP/sawdust composites. Carbohydr. Polym. 94, 800–806. https://doi.org/10.1016/j.carbpol.2013.01.080

Chen, R.S., Ab Ghani, M.H., Salleh, M.N., Ahmad, S., Tarawneh, M.A., 2015. Mechanical, water absorption, and morphology of recycled polymer blend rice husk flour biocomposites. J. Appl. Polym. Sci. 132, 1–12. https://doi.org/10.1002/app.41494

Da Silva, S.P.M., Lima, P.S., Oliveira, J.M., 2016. Rheological behaviour of cork-polymer composites for injection moulding. Compos. Part B Eng. 172–178. https://doi.org/10.1016/J.COMPOSITESB.2015.12.015

Das, O., Bhattacharyya, D., Hui, D., Lau, K.T., 2016. Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Compos. Part B Eng. 106, 120–128. https://doi.org/10.1016/j.compositesb.2016.09.020

Das, O., Sarmah, A.K., Bhattacharyya, D., 2015. A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag. 38, 132–140. https://doi.org/10.1016/j.wasman.2015.01.015

Dehghani, A., Madadi Ardekani, S., Al-Maadeed, M.A., Hassan, A., Wahit, M.U., 2013. Mechanical and thermal properties of date palm leaf fiber reinforced recycled poly (ethylene terephthalate) composites. Mater. Des. 52, 841–848. https://doi.org/10.1016/j.matdes.2013.06.022

Deka, B.K., Maji, T.K., 2011. Effect of TiO2 and nanoclay on the properties of wood polymer nanocomposite. Compos. Part A Appl. Sci. Manuf. 42, 2117–2125. https://doi.org/10.1016/j.compositesa.2011.09.023

Gozdecki, C., Wilczyński, A., Kociszewski, M., Zajchowski, S., 2015. Properties of wood–plastic composites made of milled particleboard and polypropylene. Eur. J. Wood Wood Prod. 73, 87–95. https://doi.org/10.1007/s00107-014-0852-2

Hosseinihashemi, S.K., Arwinfar, F., Najafi, A., Nemli, G., Ayrilmis, N., 2016. Long-term water absorption behavior of thermoplastic composites produced with thermally treated wood. Measurement 86, 202–208. https://doi.org/10.1016/j.measurement.2016.02.058

Hossen, M.F., Hamdan, S., Rahman, M.R., Islam, M.S., Liew, F.K., Lai, J.C.H., Rahman, M.M., 2016. Effect of clay content on the morphological, thermo-mechanical and chemical resistance properties of propionic anhydride treated jute fiber/polyethylene/nanoclay nanocomposites. Measurement 90, 404–411. https://doi.org/10.1016/J.MEASUREMENT.2016.05.006

Joel SOUCY, 2015. UTILISATION DES RÉSIDUS PAPETIERS DE DIVERSES SOURCES POUR LA PRODUCTION DE MATÉRIAUX COMPOSITES BOIS-POLYMÈRE. UNIVERSITÉ DU QUÉBEC EN ABITIBI-TÉMISCAMINGUE, Quebec.

Kashyap, S., Datta, D., 2017. Reusing industrial lime sludge waste as a filler in polymeric composites. Mater. Today Proc. 4, 2946–2955. https://doi.org/10.1016/j.matpr.2017.02.176

Klyosov, A.A., 2007. Wood-Plastic Composites. John Wiley & Sons, Inc., Hoboken, New Jersey.

Lei, B., Zhang, Y., He, Y., Xie, Y., Xu, B., Lin, Z., Huang, L., Tan, S., Wang, M., Cai, X., 2015. Preparation and characterization of wood-plastic composite reinforced by graphitic carbon nitride. Mater. Des. 66, 103–109. https://doi.org/10.1016/j.matdes.2014.10.041

Lin, Q., Zhou, X., Dai, G., 2002. Effect of Hydrothermal Environment on Moisture Absorption and Mechanical Properties of Wood Flour – Filled Polypropylene Composites. J. Appl. Polym. Sci. 85, 2824–2832. https://doi.org/10.1002/app.10844

Magarajan, U., Kumar, S.D., Arvind, D., Kannan, N., Hemanandan, P., 2018. A Comparative Study on the Static Mechanical Properties of Glass Fibre Vs Glass-Jute Fibre Polymer Composite. Mater. Today Proc. 5, 6711–6716. https://doi.org/10.1016/j.matpr.2017.11.328

Mrad, H., Alix, S., Migneault, S., Koubaa, A., Perré, P., 2017. Numerical and experimental assessment of water absorption of wood-polymer composites. https://doi.org/10.1016/j.measurement.2017.10.011

Ndiaye, D., Gueye, M., Thiandoume, C., Badji, A.M., Tidjani, A., 2015. Effects of Reinforcing Fillers and Coupling Agents on Performances of Wood–Polymer Composites, in: Green Bio Renewable Bio Composites from Knowledge to Industrial Applications. pp. 365–385. https://doi.org/10.1201/b17601-11

Nikmatin, S., Syafiuddin, A., Hong Kueh, A.B., Maddu, A., 2017. Physical, thermal, and mechanical properties of polypropylene composites filled with rattan nanoparticles. J. Appl. Res. Technol. 15, 386–395. https://doi.org/10.1016/j.jart.2017.03.008

Pǎrpǎriţǎ, E., Darie, R.N., Popescu, C.M., Uddin, M.A., Vasile, C., 2014. Structure-morphology-mechanical properties relationship of some polypropylene/lignocellulosic composites. Mater. Des. 56, 763–772. https://doi.org/10.1016/j.matdes.2013.12.033

Pothan, L.A., Thomas, S., 2004. Effect of Hybridization and Chemical Modification on the Water-Absorption Behavior of Banana Fiber – Reinforced Polyester Composites. J. Appl. Polym. Sci. 91, 3856–3865.

Poulose, A.M., Elnour, A.Y., Anis, A., Shaikh, H., Al-Zahrani, S.M., George, J., Al-Wabel, M.I., Usman, A.R., Ok, Y.S., Tsang, D.C.W., Sarmah, A.K., 2018. Date palm biochar-polymer composites: An investigation of electrical, mechanical, thermal and rheological characteristics. Sci. Total Environ. 619–620, 311–318. https://doi.org/10.1016/j.scitotenv.2017.11.076

Ratanawilai, T., Taneerat, K., 2018. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr. Build. Mater. 172, 349–357. https://doi.org/10.1016/j.conbuildmat.2018.03.266

Sanjay, M.R., Madhu, P., Jawaid, M., Senthamaraikannan, P., Senthil, S., Pradeep, S., 2018. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 172, 566–581. https://doi.org/10.1016/j.jclepro.2017.10.101

Sodeifian, G., Ghaseminejad, S., Yousefi, A.A., 2019. Preparation of polypropylene/short glass fiber composite as Fused Deposition Modeling (FDM) filament. Results Phys. 12, 205–222. https://doi.org/10.1016/J.RINP.2018.11.065

Sultan, M.T., Haque, M.M.U., Maniruzzaman, M., Alam, M.A., 2015. Composites of polypropylene with pulque fibres: Morphology, thermal and mechanical properties. J. Thermoplast. Compos. Mater. 28, 1615–1626. https://doi.org/10.1177/0892705713513295

Turku, I., Kärki, T., 2016. Accelerated weathering of fire-retarded wood – polypropylene composites. Compos. PART A 81, 305–312. https://doi.org/10.1016/j.compositesa.2015.11.028

Turku, I., Keskisaari, A., Kärki, T., Puurtinen, A., Marttila, P., 2017. Characterization of wood plastic composites manufactured from recycled plastic blends. Compos. Struct. 161, 469–476. https://doi.org/10.1016/j.compstruct.2016.11.073

Wang, M., Fan, X., Thitsartarn, W., He, C., 2015. Rheological and mechanical properties of epoxy/clay nanocomposites with enhanced tensile and fracture toughnesses. Polymer (Guildf). 58, 43–52. https://doi.org/10.1016/J.POLYMER.2014.12.042

Wang, W., Zhang, X., Mao, Z., Zhao, W., 2019. Effects of gamma radiation on the impact strength of polypropylene (PP)/high density polyethylene (HDPE) blends. Results Phys. 12, 2169–2174. https://doi.org/10.1016/j.rinp.2019.02.020

Zhang, H., 2014. Effect of a novel coupling agent, alkyl ketene dimer, on the mechanical properties of wood-plastic composites. Mater. Des. 59, 130–134. https://doi.org/10.1016/j.matdes.2014.02.048

Zhou, X., Yu, Y., Lin, Q., Chen, L., 2013. Effects of Maleic Anhydride-Grafted Polypropylene (MAPP) on the Physico-Mechanical Properties and Rheological Behavior of Bamboo Powder-Polypropylene Foamed Composites. BioResources 8, 6263–6279.

Zhou, X., Zhang, P., Jiang, X., Rao, G., 2009. Influence of maleic anhydride grafted polypropylene on the miscibility of polypropylene / polyamide-6 blends using ATR-FTIR mapping. Vib. Spectrosc. 49, 17–21. https://doi.org/10.1016/j.vibspec.2008.04.004